actionhobby.ca

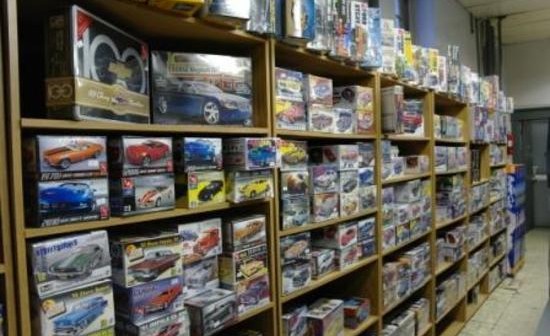

Welcome. We're a 'mom & pop' store front hobby shop offering a selection of radio controlled planes, cars, trucks, and boats. We offer a substantial selection of replacement parts and pride ourselves on our special order service for product we don't normally stock. We also have a selection of plastic models, rockets and kites.

Doug & Donette Hyslip - selling fun since 1991

Contact Us

actionhobby.ca

#A - 7012 Ogden Road S.E.

Calgary AB T2C 1B4

Telephone: (403) 236-5098

Email: info@actionhobby.ca

Website: www.actionhobby.ca

Facebook: www.facebook.com/ActionHobby/

Hours

9:30 am - 6:00 pm, Monday through Saturday

Closed 3-Day Long Weekends

Map

Promotions

March

Winning Invoice

For

$300 Gift Certificate

MA241594

Announcements

Mar 25, 2024

We will be closed Friday March 29 - Sunday March 31 for Easter weekend! Stay safe everyone and have a great Easter!

Mar 23, 2024

- New in Stock: FMS 1/18 K10, FMS 1/18 Trailer, FMS Parts, FMS FMT24 Monster Truck!

- Back in Stock: Traxxas TRX4M F-150 Ranger!

Mar 21, 2024

- New in Stock: Traxxas Maxx Slash!

Mar 13, 2024

- New in Stock: Associated RC10CC Clear Chassis Kit Edition, Redcat Everest18, Everest18 Parts, Enduro Sendero HD Black And the Micro Draco BNF Basic!

- Back in Stock: Arrma Granite Grom in Green, Redcat Everest Ascent, and More Book Nooks!!!

Mar 6, 2024

- New in Stock: XMaxx Ultimate!

- Back in Stock: Arrma Gorgon and the Arrma Grom!

Mar 1, 2024

For the month of March all kites are 10% off!! Come on down while quantities last!